New machines Biezepol Metalworking.

Biezepol invested in a number of new machines in the second quarter of this year. Under the guise of ‘aging is regression’, the following machines were purchased:

Kasto SSB A2 sawing machine:

The sawing process is often underestimated. It should not be forgotten that before production can start, a sawn raw product must be ready.

To ensure that the supply of these raw products runs smoothly, the industrial sawing machine from Kasto was chosen. The old sawing machine has completed its task and is being replaced.

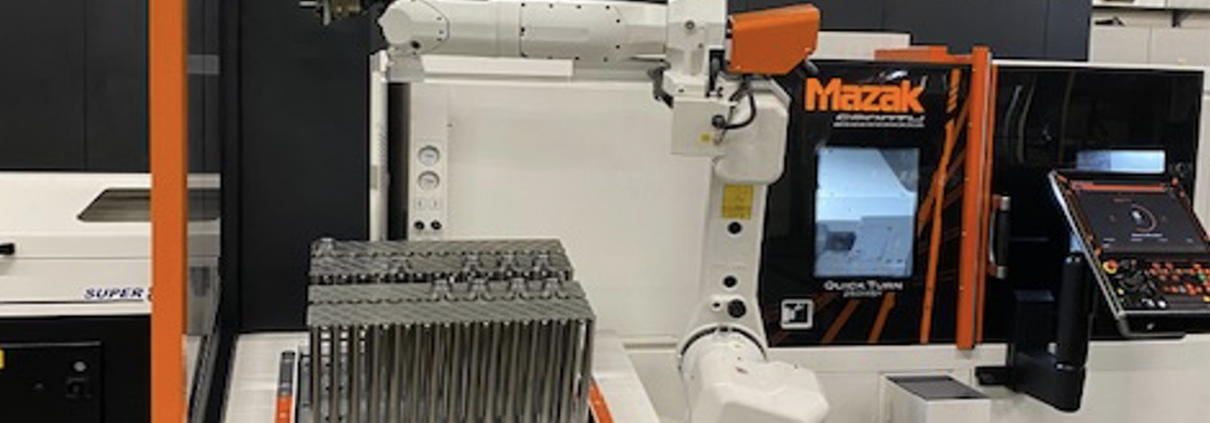

Robojob Mill Assist:

This will be the first step towards automating our milling department. The robot will be placed at the Mazak Variaxis and should ensure improved productivity in the evenings.

All these machines obviously need pneumatics to function. To keep this process reliable, a new compressor has also been purchased. The current type has proven itself to be a solid machine. That is why the Kaeser brand was chosen again.